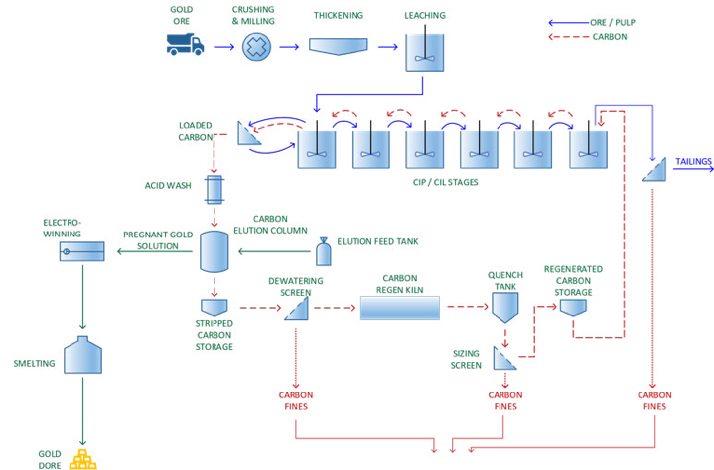

Talis Mining excels in the field of minerals and metals processing, with a particular focus on an innovative technique for extracting gold from carbon fines. Carbon fines processing involves the careful management of tiny carbon particles generated as a by-product of various industrial processes.

Our carbon fines incinerator uses a thermal process that effectively burns carbon and other combustible materials, while efficiently capturing the gold ash through a high efficiency filtration system.

This optimised approach has produced remarkable results, including significantly reduced levels of unburned carbon, successful separation of much of the grit and silica from the ash, improved fuel efficiency and exceptionally high levels of gold recovery. This commitment to advanced processing techniques reflects our commitment to improving operational efficiency and sustainability in the minerals and metals sector.

The Carbon Fines process is a well-established technique utilised for the extraction of gold from carbon fines that have been separated from the elution circuit.

The carbon fines process employs a thermal method to consume carbon and other combustible materials, while effectively capturing gold ash through a filtration system with great efficiency.

The process has been tuned to achieve a significant reduction in unburnt carbon, effective separation of a majority of the grit and silica from the ash, enhanced fuel economy, and exceptional levels of recovery.

The separation of fine Carbon from grit

The initial stage in the processing of contaminated fine carbon is of utmost importance, as it involves the crucial task of separating the fine carbon from grit particles. Talis Mining Services employs exclusive technology, specifically a spiral and a flotation cell, for the purpose of coal purification. The average recovery rate for this procedure is around 96%, as determined by prior operational assessments.

The removal of sand silica from carbon is of utmost importance in subsequent procedures, such as burning.

This aids in guaranteeing that the procedure is self-sustaining and effective.

The commencement of this procedure can be initiated around six months prior to the installation of the incinerator, allowing for the establishment of a practical stockpile.